With the misinformation swirling around the topic of moisture in concrete roof decks, it can be difficult to know the right approach to take to mitigate risk.

- Are roof failures due to moisture in concrete primarily found in lightweight concrete decks?

- Do vented decks alleviate moisture in concrete by facilitating downward drying?

- Is 28 days the right amount of time to let a new concrete deck cure?

- Are admixtures and MVRA's (Moisture Vapor Reduction Additives) effective in mitigating concerns around moisture in concrete roof decks?

- Are vapor retarders the answer? What about vented base sheets?

- What adhesives and insulation and cover board facers are appropriate to use in these roof assemblies?

It's well known in the industry that excessive moisture in concrete roof decks can lead to poor performance of adhesively installed roof assemblies. These performance issues can range from biological growth to roof failures. The industry is still learning about the causes of these failures, and what doesn't work to mitigate the issue. However, there are some basic facts that are often confused, and compounded by out of date information that is still in circulation. This article will attempt to debunk some of the myths.

How this started

Traditionally, when adhered systems were installed, insulation boards were adhered direct to the concrete deck with hot applied asphalt. The continuous layer of asphalt that bonded to the concrete deck functioned as a vapor retarder, mitigating the impact of latent moisture in the concrete from negatively impacting the roof system.

In the late 1990's, newer technologies became popular in the roofing industry, displacing the traditional asphaltic based application methods. Insulation boards were now able to be installed with solvent based and water based adhesives or low-rise foam adhesives.

Beginning in 2000, there was an increase in reported moisture related issues with roofs installed over new concrete roof decks, including moisture accumulation, adhesion loss, adhesive issues with water-based and low-volatile organic compound adhesives, metal and fastener corrosion, insulation R-value loss and microbial growth1. Compounding the problem, restrictions on VOC content in materials resulted in the use of more water based adhesives, which can be "much more susceptible to re-emulsification when exposed to moisture, depending on the adhesive formulation."2

Fact or Fiction

"Moisture in concrete is only an issue with lightweight structural concrete."

As the industry began to pay attention to increased reports of moisture related issues with roofs installed over new concrete roof decks in the 2000's, it was noted that many of these roof failures were primarily over lightweight structural concrete roof decks.

Lightweight aggregates, which are typically an expanded shale, can hold more initial water than traditional 'hard rock' aggregate found in normal weight concrete. According to the NRCA, lightweight aggregates absorb 5 to 25 percent water by weight, where normal weight concrete aggregates typically absorb less than 2 percent water by weight. NRCA's calculations3 indicate that after the 28 day cure time, nearly 3 times the amount of free water can be present in a 6-inch lightweight structural concrete deck than a normal weight concrete deck.

Figure 1: Water added to and remaining in example concrete mixes

FM Global's Loss Prevention Data Sheet (LPDS) 1-29 provides additional requirements for roof systems over lightweight structural concrete, stating that "a great deal of moisture will be released for several months after the concrete has hardened and will be absorbed by above-deck components. This will damage and weaken those components, resulting in damage from winds below design speeds, or premature deterioration requiring replacement."4

While the increase of moisture related issues were initially associated with lightweight structural concrete, by 2015 the number of lightweight structural concrete cases were proportional to normal weight structural concrete cases, indicating that the extra free evaporative moisture in the lightweight aggregate was not the sole cause of the moisture related roof failures.5 Therefore, both normal-weight and lightweight concrete types are now known to be a risk factor for new roof systems. It should be noted, however, that the NRCA and some manufacturers still recommend avoiding lightweight concrete in roofing applications.

"Vented composite decks significantly enhance downward drying."

The use of non-removable forms or composite steel and concrete decks has significantly increased over the past 30 years. These decks allow for much shorter construction timelines, eliminating much of the expense of building and stripping temporary form structures, and are structurally efficient. However, by leaving the steel formwork in place at the bottom of the concrete slab, the concrete can not dry to the underside. Therefore, the roof deck retains a significant amount of water as there are very limited pathways to allow for drying out.

There is an option to vent the steel form deck, which may facilitate some amount of downward drying. However, according to the IIBEC Technical Advisory Bulletin on Roof Covering Systems and New Concrete Roof Decks (IIBEC TA-020-2021), "steel pan decks, whether vented or non-vented, function essentially as a vapor retarder located beneath the concrete, which significantly reduces the amount of drying that can occur from the bottom side of the concrete."

Figure 2: The actual venting achieved by vented metal decks is not yet quantified.

Vented metal decks may allow for some drying of the concrete deck. However, there is no published data to quantify the actual venting achieved. It is presumed to be of "minimal value with respect to downward drying."2 In fact, FM Global's LPDS 1-29 requires additional design considerations beyond a vented metal deck stating that "it will have limited impact on moisture reduction." And, the Steel Deck Institute's Position Statement titled, Venting of Composite Steel Floor Deck" states "The steel deck acts as a vapor barrier...a hypothetical 1.5% open area will increase the diffusion of water by 1.5%, an inconsequential amount."

"Concrete Decks are ready to roof after a 28 day cure"

Water takes a long time to diffuse out of what is typically a four to six inch-thick composite concrete deck. The inherent moisture migration in the concrete structure is exacerbated by new concrete mix designs and the cascading adhesion problems that can occur in roof systems. Significant amounts of water remain after curing is completed, even moreso when lightweight aggregates are incorporated into the mix design.

The historical 28-day cure period for concrete is to achieve appropriate concrete strength and has little significance or correlation to the moisture contained within the concrete. In concrete roof decks, there is very little correlation between cure time and the amount of water remaining. Guideline "rules of thumb," such as not installing the roof system until a minimum of 30 days after pouring and forming, are not particularly effective at reducing or eliminating issues. Assembly design such that moisture doesn't enter the roof assembly is key versus rules of thumb.

"The plastic mat test is the most effective way to evaluate dryness"

Currently, there is no consensus within the roofing industry on an acceptable standard for evaluating the moisture content nor acceptable moisture content levels in concrete roof decks.

Historically, three tests were generally used by the roofing industry to evaluate concrete roof decks. These qualitative test methods were thought to provide visual evidence of unacceptable moisture levels.

- The Plastic Mat Test (ASTM D4263, Standard Test Method for Indicating Moisture in Concrete by the Plastic Sheet Method)

- Hot Asphalt Pour and Peel Test (NRCA Test Method)

- Calcium Chloride Dome Test (ASTM F1869, Standard Test Method for Measuring Moisture Vapor Emission Rate of Concrete Subfloor Using Anhydrous Calcium Chloride)

The plastic mat test involves securing a plastic sheet to the roof deck and observing condensation accumulation. The Pour and Peel test method involves pouring hot asphalt onto the roof deck, looking for bubbles or frothing, and examining the quality of the adhesion. And the Calcium Chloride test involves placing a canister of the powder under a plastic dome and measuring the amount of water evaporation collected over a 24 hour period.

Figure 3: The plastic mat test, the hot asphalt pour and peel test, and the calcium chloride dome test are no longer considered reliable to evaluate the dryness of concrete decks for roofing purposes.

These evaluation methods are only reflective of surface moisture and are not effective in detecting moisture levels in lower portions of the concrete slab.2 The industry no longer considers these tests reliable to evaluate concrete roof decks.

The standards and acceptable threshold levels used by the flooring industry do not directly translate to roofing as the concrete roof slab does not exist within the conditioned space and is exposed to the elements. The flooring standard requires conditioning of both the concrete slab and the air above it to a constant service temperature and relative humidity for at least 48 hours. However, this is not feasible for a roof deck. Additionally, the moisture content of the concrete currently exceeds the measurement capability of the in-situ probes used in ASTM F2170.3

"Admixtures / MVRAs will prevent moisture related issues"

Moisture Vapor Reducing Admixtures (MVRAs) are concrete admixtures intended to address moisture in concrete by effectively shutting down moisture vapor movement through the concrete, and MVRAs purportedly deliver a slab that requires no further moisture tests, and no additional topical moisture mitigation systems.6

The concept is to turn the concrete slab into a vapor retarder, slowing the release of its own moisture into the roof system. However, there currently is little to no technical data to substantiate marketing claims made by the vendors of MVRAs nor their ability to lower the water vapor transmission of the concrete by a significant amount.

NRCA partnered with RDH Building Science Laboratories7 to conduct some roofing industry specific research on MVRAs. This study shows permeability values of the concrete roof deck cores with MVRA to be greater than those without MVRA. These test results contradict claims that MVRAs minimize the concrete's ability to release moisture vapor.

To date, MVRAs have been shown in the laboratory and field to have no effect on moisture issues in roof systems. Therefore, their use is not recommended to address the moisture in concrete concerns for roof decks.3,7

Are vapor barriers the answer?

Vapor retarders are designed to reduce vapor diffusion. A class 1 vapor retarder has a perm rating of 0.1 perms or less, and is often referred to as a vapor barrier. A vapor retarder, installed against the concrete, is necessary for expected roof system performance in all but ASHRAE Zone 1.3

Do you specify a class 1 self-adhered vapor retarder over your concrete deck, and believe this has mitigated the risk of moisture in concrete?

While the initial bond of the self-adhered vapor barrier to a "wet deck" may result in acceptable adhesion, what happens when it's exposed to upward vapor drive from curing concrete for a year, or two, or five? It is possible that the bond would be insufficient over time as the moisture migrates out of the roof concrete slab over a period of years, as demonstrated by the SRI Research Report.

To make matters worse, often subsequent layers of roof insulation and roof membrane are also adhered together, relying on the initial self-adhered vapor barrier's bond to the "wet deck" to attach the entire roof system. Insulation facers can delaminate from the substrate or the insulation core and membranes that appear to be initially adhered can lose adhesion due to moisture migration.

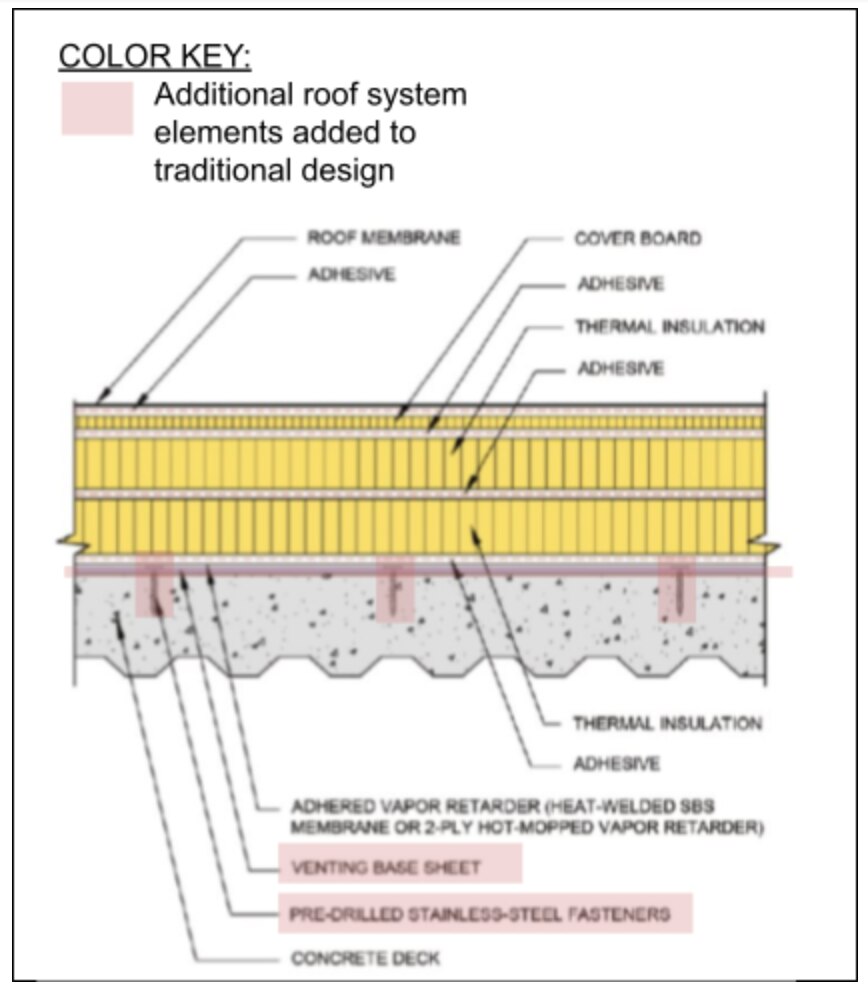

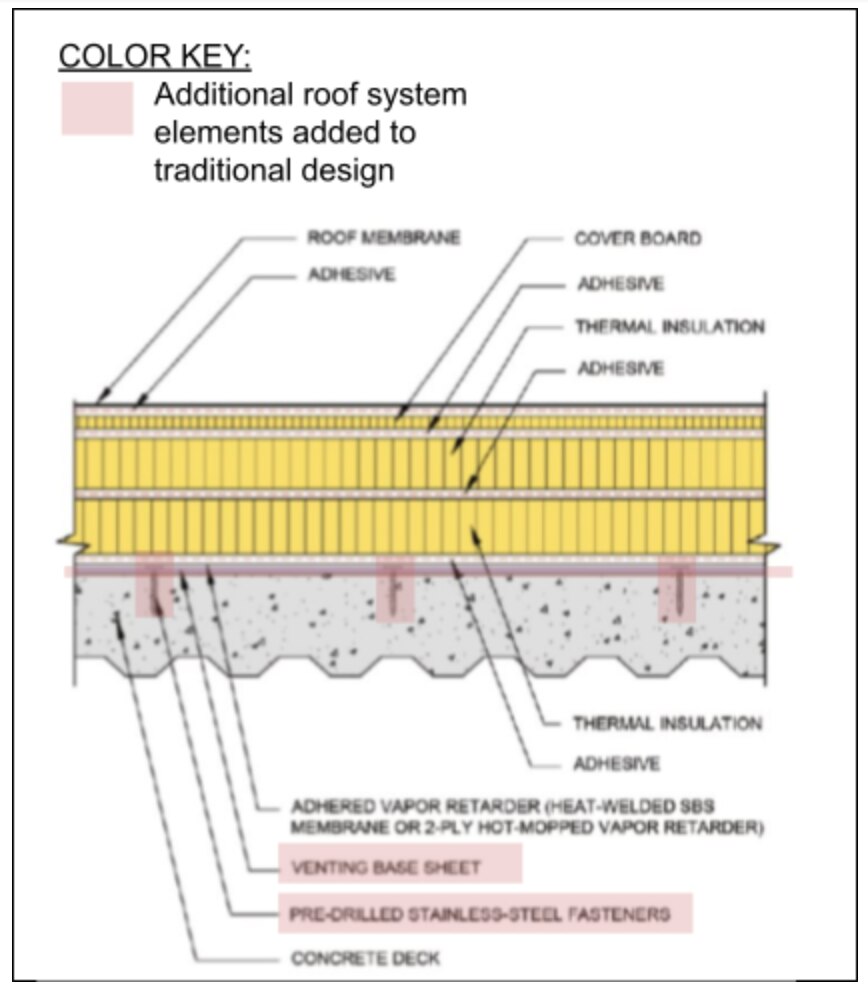

While vapor barriers can be a necessary part of roof systems installed over concrete decks, the traditional "rules of thumb" may not be enough. The concerns around long-term adhesion to the concrete deck are leading contractors and designers to consider additional steps to keep the roof system attached to the building. In a recent article,8 the authors provide six alternate design configurations and attachment methods to navigate various scenarios and the attachments, assembly layers, and the fundamental physics that are at work across the interconnected structure and roof systems. Below in Figure 4 is an example of one of the scenarios provided, with the non-traditional design elements highlighted in red for clarity.

Figure 4. Example of added roof complexity from evolving structural design

Today's Best Practice

There is certainly a lot of complexity and confusion swirling around moisture in concrete as it relates to roofing. However, there are a few useful industry guidelines to leverage, including the NRCA Roofing Manual, the IIBEC Technical Bulletin, and the Moisture in New Concrete Roof Decks research report by SRI Consultants.

- Determine in the design phase if the roof deck needs to incorporate concrete for structural, fire, or other reasons. If not, consider a metal deck with a compact roof system above

- Limit the water-cement ratio for both normal weight and lightweight concrete

- Pour concrete onto a strippable form when possible; or at least a vented metal deck

- Allow adequate time in the construction schedule for initial slab drying and protect the slab from re-wetting where possible

- Utilize a vented base sheet above the concrete slab where possible

- Install a class 1 vapor retarder (less than 0.01 perms) direct to the concrete deck

- Eliminate the use of water-based primers or adhesives for the insulation and roof membrane attachment, such as using a low-rise foam adhesive

- Consider mechanical fastening the roof assembly into the concrete deck

- Use of coated glass-faced insulation boards and coverboards in lieu of paper faced boards

Specify a roof manufacturer's specific assembly that is designed and tested for wind uplift resistance over concrete decks. Additionally, consider the long term adhesion performance of the vapor barrier when the assembly relies on the adhesion for wind uplift resistance.

Sources Used

1Professional Roofing Magazine – Moisture in Concrete Roof Decks by Mark Graham; February 2017

2IIBEC Technical Advisory Bulletin Roof Covering Systems and New Concrete Roof Decks 02-2021

3Professional Roofing Magazine – What You Can't See Can Hurt You by Mark Graham; August 2012

4https://www.fmglobal.com/-/media/Documentum/Data-Sheet-Individual/01-Construction/FMDS0129.pdf?isGated=true&itemId={A6F00C1A-1B78-40C0-A72E-CEB0702FD38F}

5Moisture in New Concrete Roof Decks research report by SRI Consultants

6ISE Logik Industries MVRA 900 marketing literature

7Professional Roofing Magazine – Putting it to the Test by Mark Graham; February 2020

8Interface Magazine – Structural Concrete Decks, Vapor Retarders, and Moisture – Rethinking What We Know by Helene Hardy Pierce and Joan Crowe; February 2020