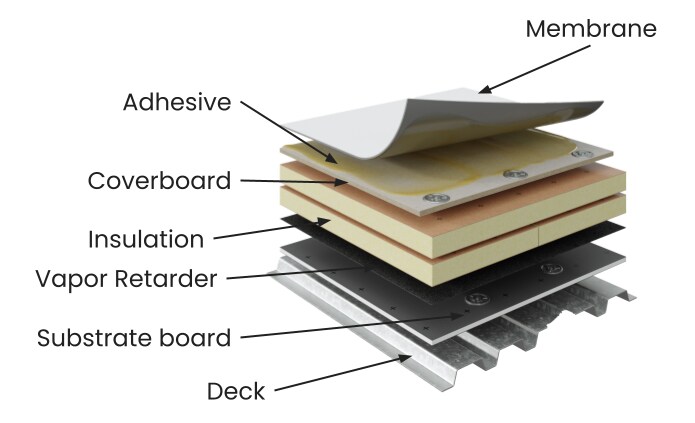

Single-ply roof membranes are a common choice for commercial low-slope roofing projects due to its durability, reflectivity, and ease of installation. The membrane is the top of a multi-layer assembly designed to help protect the building from the exterior elements. The layers of a roof assembly must all work together with two main goals: help keep the interior separate from the exterior (i.e. block the movement of water, air and heat between inside and out) and stay in place through expected weather conditions.

The roof assembly layers contribute to these goals in different ways depending on the choice of materials, their locations within the assembly, and how well they are protected from damage caused by elements such as wind, hail, or foot traffic. Whether you're a designer, specifier, or building owner, understanding these components and how they work together is key to ensuring superior roofing performance, efficiency, and longevity.

Components of a Single-Ply Roofing System

A typical single-ply roofing assembly consists of the following layers, in order from bottom to top:

Roof Deck

The roof deck is the layer that provides continuous horizontal structural support and stability for the other layers of the roof assembly. Roof decks span the building's structural beams, joists, or trusses and are usually made of steel, wood, concrete, or a combination thereof.

Substrate Board

The substrate board is an optional layer that's commonly made of high-density polyisocyanurate (polyiso), gypsum (with or without glass mat), or wood fiber. It's usually installed on metal roof decks to provide a continuous, even substrate for the subsequent layers, especially an air barrier and vapor retarder. The substrate board may also be a thermal barrier in the assembly.

Vapor Retarder and Air Barrier

A separate vapor retarder, if needed, is best installed on the roof deck or substrate board. The purpose of a vapor retarder is to minimize water vapor diffusion into the roof assembly, preventing vapor from penetrating into the other layers of the assembly and causing condensation damage. Vapor retarders typically take the form of self-adhered sheet membranes or a modified bitumen base layer. The National Roofing Contractors Association recommends that a vapor retarder should always be installed on a concrete deck, on any roof deck in buildings with high interior humidity (like a natatorium or a gym), and in colder climates. Vapor retarders are not a requirement in the building code (2024 IBC 1404.3).

An air barrier controls air flow between the interior and exterior of a building, a process that can carry significantly more moisture into a building than vapor diffusion. Since 2012, continuous air barriers have been required on buildings in most climate zones by the model energy code. All vapor retarders have the capability to act as air barriers if they are properly detailed, but not all air barriers have a low permeance such that they stop vapor diffusion. Check out this blog for more information on air barriers & vapor retarders.

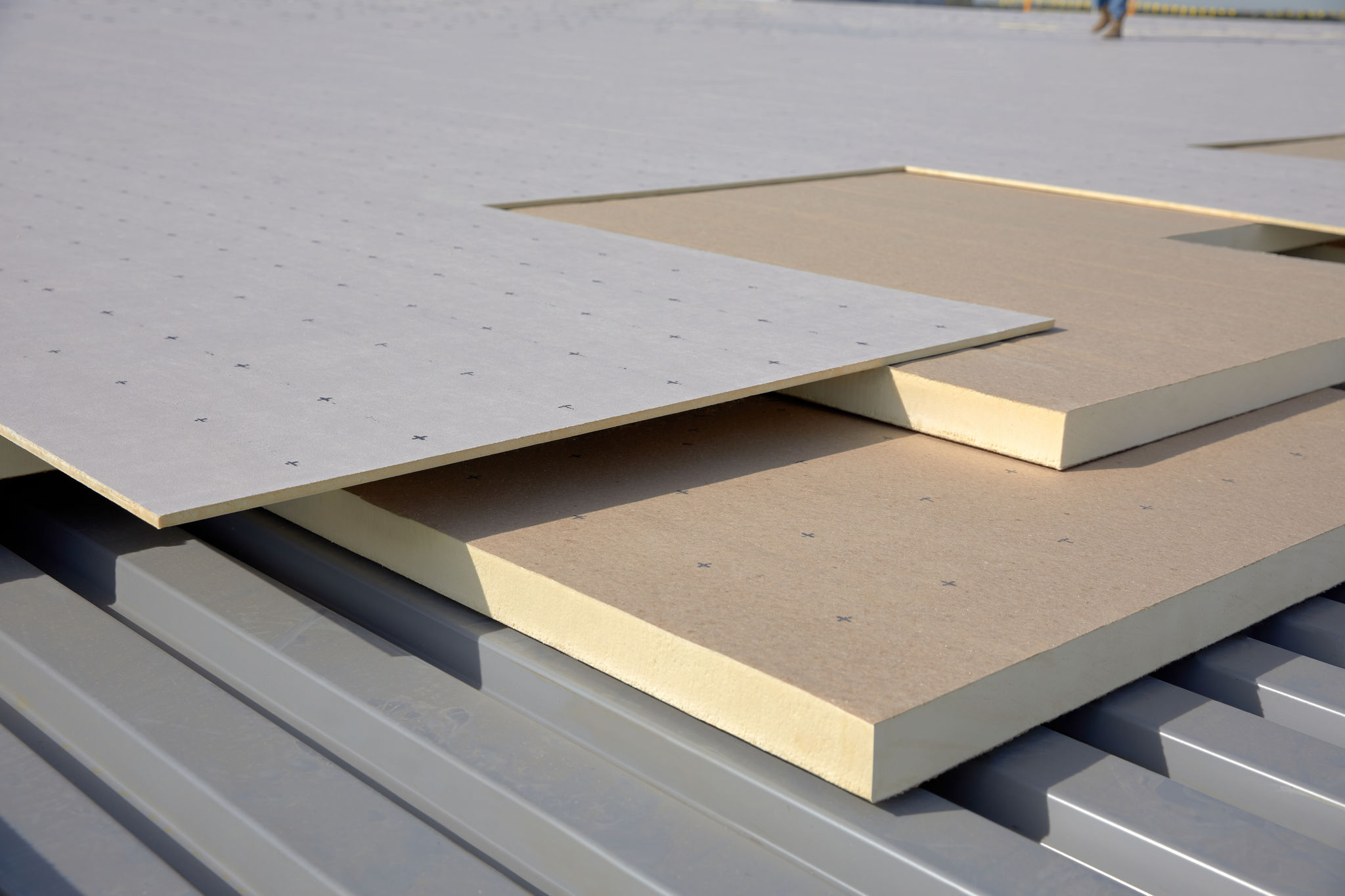

Insulation

Insulation provides thermal resistance that helps prevent heat from moving between the building and the exterior environment. It can help enhance the comfort of occupants while improving the energy efficiency of the building by reducing heating and cooling costs. Polyisocyanurate (polyiso) accounts for approximately 70% of the roof insulation currently being installed as part of a single-ply roofing assembly. Other commonly used materials include extruded polystyrene (XPS), expanded polystyrene (EPS), mineral wool and vacuum insulated panels (VIPs).

Since 2018, the International Energy Conservation Code has required two layers of insulation, staggered and offset, to minimize air intrusion into the roof assembly.

When the roof structure is not sloped to drain itself, the use of tapered insulation and crickets may be necessary to direct bulk water to drains and avoid ponding water on the roof. For more information on tapered insulation, contact our Tapered Design Team.

Coverboard

The coverboard is installed on top of the insulation to protect it from impacts such as hail or heavy foot traffic, and may add fire resistance. Coverboards may also increase the wind resistance of the roof assembly.

While coverboards are optional in many roof assemblies, they are required for most very severe hail assemblies and are strongly recommended when there is overburden on the roof, such as solar panels.

Coverboards are made of high-density polyiso, glass mat or standard gypsum, cementitious materials, perlite and wood. Depending on the material, a cover board can also serve as an additional thermal barrier, thus increasing the R-value of the assembly or possibly reducing the thickness of the insulation required below it.

Single-Ply Roofing Membrane

The roofing membrane is the outermost weather-proofing layer of the assembly, which serves as the first line of defense against external forces acting on the roof. If a separate air barrier is not installed, it can also help serve as the air barrier layer if installed correctly, with careful attention to joints, penetrations, and transitions.

The main types of single-ply roofing membranes are TPO, PVC, PVC KEE, and EPDM. Check out this blog to learn more about the types of single-ply membranes and their attributes.

Selecting the Right Assembly

A high performing roof assembly requires more than just a set of materials stacked together without a plan. Building type, climate zone, and local code requirements all play important roles in determining the selection of components and their placement within a single-ply roofing assembly.

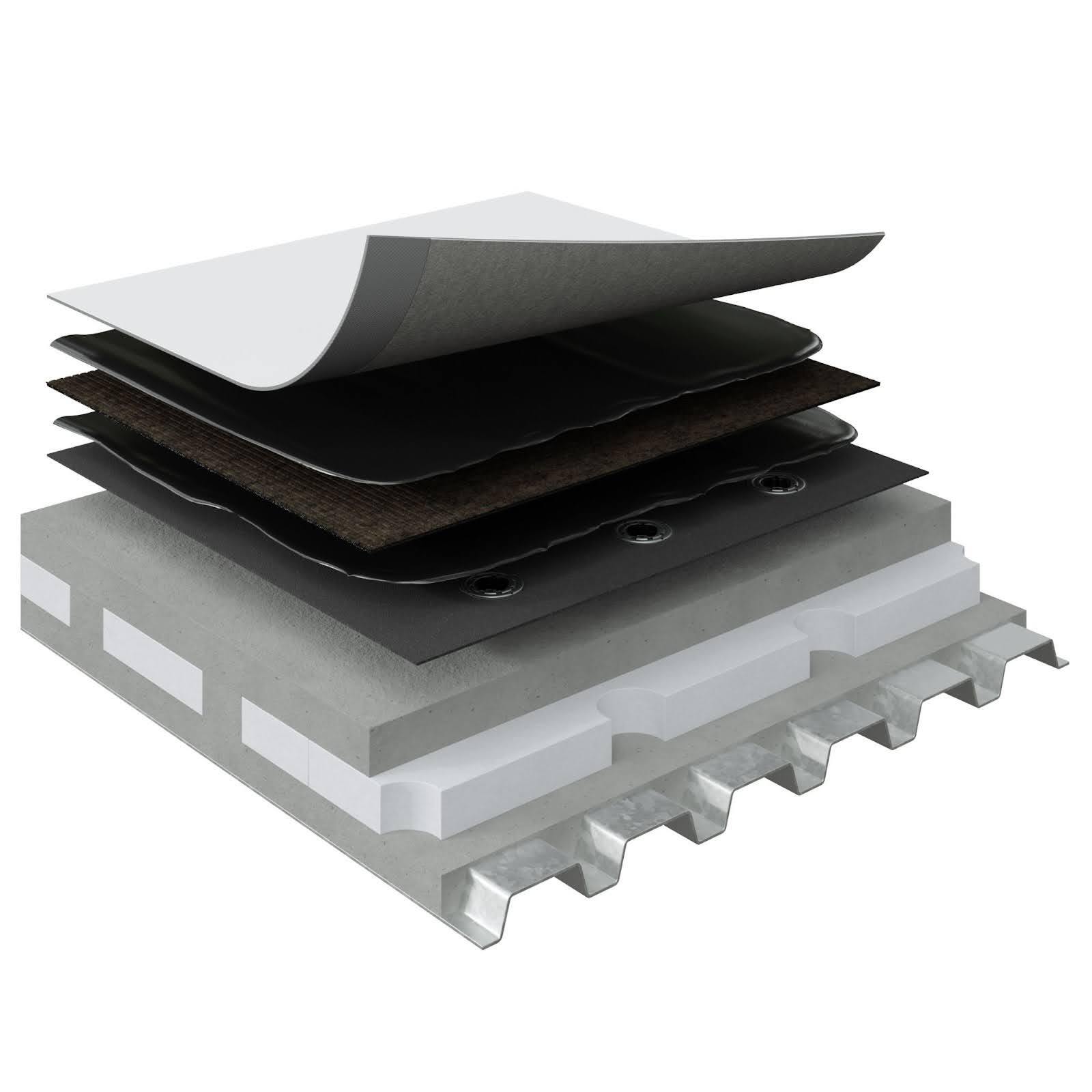

Attachment Method Impacts

The attachment method should be evaluated as part of the entire roof assembly. Attachment methods include mechanical, induction-welded, fully adhered, ballasted, self adhered or a combination of two or more methods. The membrane as well as the rest of the roof assembly must be attached to the structure by way of the deck. The attachment method should be carefully chosen based on building type, climate zone, thermal efficiency requirements, wind loads and compatibility with other single-ply roof assembly layers.

While mechanical attachment is a quick and economical method, it's not recommended in locations with severe hail or windstorms that could damage exposed attachment plates, allowing infiltration of water or moist air into the assembly. Mechanically attached assemblies also are expected to have more billowing of the roof membrane than adhered membranes. In these conditions, a different attachment approach may be considered: the first layer of insulation or the substrate board is mechanically attached, but subsequent layers are adhered. This results in an assembly with no exposed fasteners. This method also reduces the thermal bridging in the assembly, resulting in a higher effective R-value.

The attachment method also impacts the roof assembly performance in other specific design scenarios.

Location Specific Considerations

Wind uplift requirements for the roof assembly are based on the project enclosure, exposure, and risk category as well as the geographic location. When the calculated wind uplift pressures

Once the wind uplift pressures are calculated and the desired roof assembly is selected, then the attachment methods can be evaluated. High wind uplift pressures may result in limitations to the attachment options such as only mechanically attached options or only certain adhesives that may be used.

Very severe hail has very specific assembly requirements, especially for FM insured buildings located within the very severe hail zone. To achieve a very severe hail classification, the full roof assembly is tested. This includes the membrane, coverboard, insulation and the attachment method(s). Very few mechanically attached assemblies meet this requirement, and glass mat coated gypsum coverboards are usually required.

In both the case of wind uplift resistance and hail or impact durability, coverboards can play an important role. A coverboard with a glass mat gypsum or cementitious core is recommended if the building is in a location where severe hailstorms could damage the roof. Gypsum and cementitious boards also provide a high degree of fire resistance. If extremely high impact resistance isn't needed, high-density polyiso coverboards provide a cost effective, user friendly option that also provides additional assembly durability while also providing additional thermal efficiency.

Importance of Layer Compatibility

Specifying the right type and combination of single-ply roof assembly layers ensures that potential issues that lead to problems later can be avoided.

One example of potentially incompatible roof assembly layers is the installation of a single-ply roofing membrane over a modified bitumen roof membrane or accessory material. There is a chemical incompatibility between modified bitumen and thermoplastic membranes, so a physical separator must be present. This can take the form of a fleece-backed single-ply membrane or it can be a separate layer such as a slip sheet or cover board under the single-ply membrane. This may be seen in a hybrid roof assembly or when re-covering an existing mod-bit roof with a single-ply.

Designing for Moisture Vapor Movement

In colder climate zones, building codes often require thicker insulation layers to provide the required R-value as well as a vapor retarder on the roof deck to prevent moisture vapor from diffusing into the roof assembly during the heating season. Ideally, the vapor retarder is also installed as an air barrier, preventing moisture vapor in the air from leaking or intruding into the roof assembly. In both cases, it reduces the risk of condensation within the roof assembly.

However, there may be a potential issue when an impermeable vapor retarder is installed in a non-airtight manner and/or where inward drying of the single-ply roofing assembly is necessary after construction is complete. Vapor retarders are classified based on their degree of permeability, or how much water vapor passes through them over a set period of time. If vapor is unintentionally trapped within a single-ply roofing assembly with no way to escape, it could lead to moisture issues such as material deterioration or biological growth. Certain situations may call for a more permeable vapor retarder to allow some water vapor to diffuse out of the assembly.

Nailing the Details

Successful roof assemblies also heavily depend on robust details. This includes penetrations through the field of the roof, base-flashing and termination details and edge metal selection.

The most common solution for sealing penetrations through the field of the roof of a single-ply membrane is to use the same material. This can be field-fabricated corners and pipe boots, or installers can use pre-manufactured accessories. Pre-manufactured pipe boots, corners and scuppers reduce the installation time compared to highly workmanship reliant field-fabricated details. Another option for penetration details is the use of liquid-applied materials such as PMMA or PUMA. PMMA is not compatible with TPO membranes, but can be an effective option for complex details through PVC membranes.

Securing the edge of the roof is just as important as making the field of the roof watertight. This requires the use of base flashing and attachment around the roof perimeter, as well as the use of termination bars in many parapet conditions. Finally, the selection of edge metal that meets the wind design loads for the project is critical. The edge is frequently the first point of failure during a high-wind event, so the design and selection can have a strong impact on the life-expectancy of the roof assembly. The building code requires the use of ES-1 compliant edge metal, which can be easily accomplished using pre-manufactured materials.

Preparing for Roofing Success

When specifying a single-ply roofing assembly, it's important to take time to consider each layer of the assembly, its role in protecting the building and how it will work together with the other components. A reputable and experienced manufacturer can provide options to help ensure all roof assembly components are appropriate and compatible for your project. GAF offers a wide range of resources for design professionals and building owners. The GAF | Siplast Building & Roofing Science team has experts that are available to answer your questions. They can be reached at buildingscience@gaf.com.