Coverboards can be important components of commercial roof assemblies. They can increase the resilience and durability of the roof by helping it better withstand environmental exposure, wind uplift, and long-term wear. In certain circumstances, coverboards can be absolutely essential to the longevity of a roofing system.

So, what exactly are coverboards? And in what situations should you specify one? Let's take a closer look.

What Is a Coverboard?

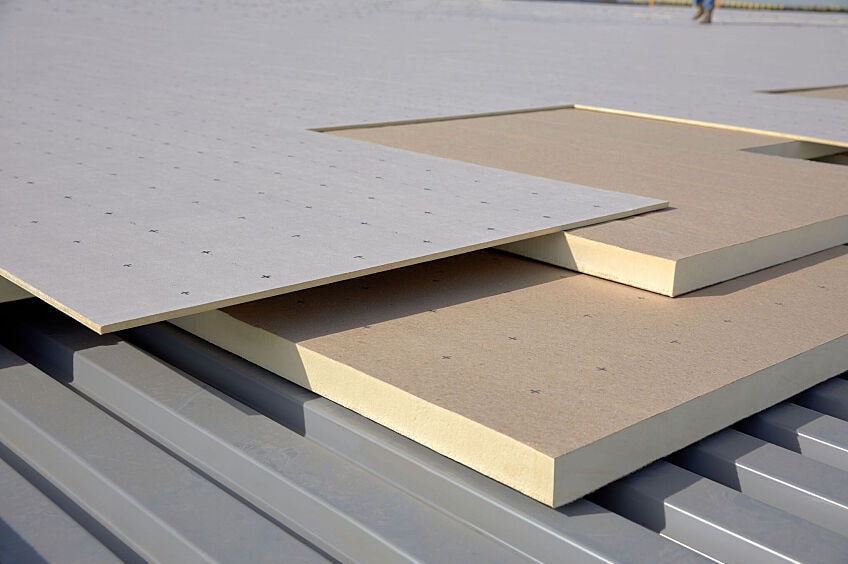

A coverboard is a thin, dense substrate installed between the insulation and the top waterproofing membrane of the roof. It can help protect the roof from various types of impacts, protect the insulation from damage and, ultimately, help provide extra protection for the entire roof assembly. It can also provide a stable surface for the installation of the roof membrane and any overburden while increasing the roof's wind uplift resistance.

Top 5 Reasons to Specify a Coverboard

There are certain high-risk and high-performance scenarios in which the installation of a coverboard is imperative. They include:

1. Hail-Prone Regions

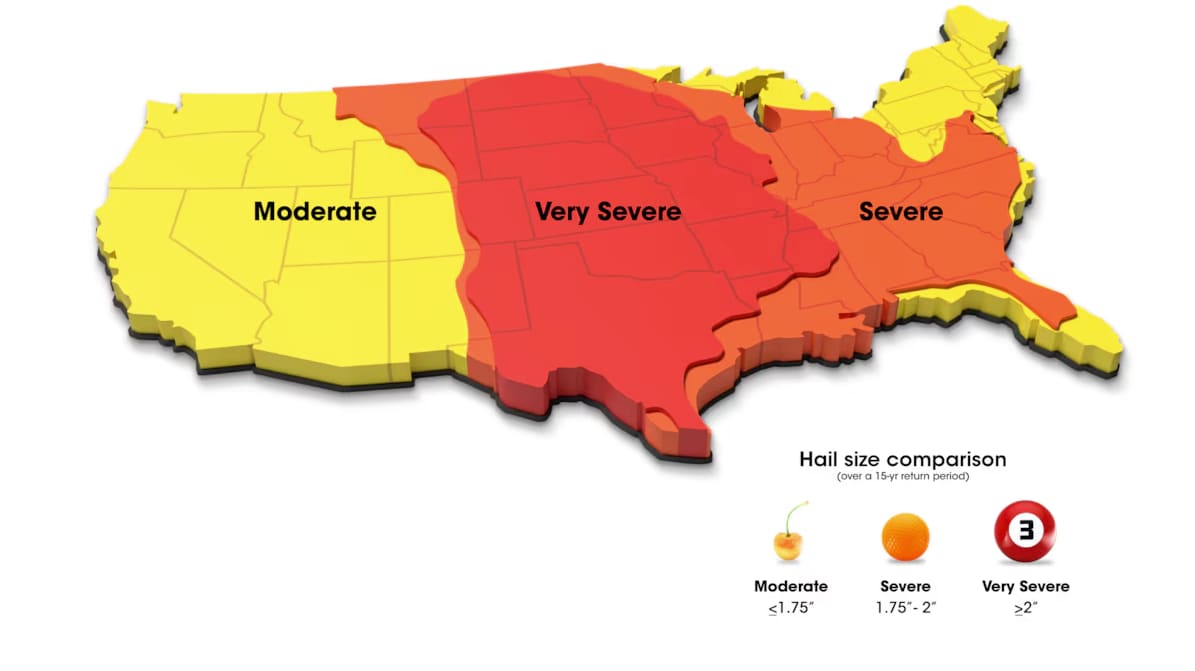

Due to the accelerating impacts of climate change, nearly two-thirds of the U.S. is now susceptible to the damaging effects of hailstorms. Factory Mutual (FM) has identified certain areas of the country by hail zone, ranging from Moderate to Severe and Very Severe. If your project is in a Very Severe Hail (VSH) region, FM requires the buildings it insures to meet the requirements for a VSH assembly, which often includes a heavy-duty glass-mat gypsum coverboard, like DensDeck® StormX™ Prime.

The attachment method of the roof membrane can be equally important, since mechanical attachment can lead to membrane damage when hail strikes the membrane at fastener locations. For this reason, it is recommended that the coverboard and the roof membrane both be adhered, burying the fasteners deeper in the assembly and providing better membrane protection.

Adhering the assembly layers also has the benefit of minimizing the effects of thermal bridging, which can cause a significant drop in effective R-value. Even if your project is not in a VSH zone, it is worth considering the extra protection a gypsum coverboard can help provide if your building is subject to severe or moderate hail*. More hail system resources can be found here.

2. Rooftop Solar Installations

Photovoltaic panels mounted on a roof impose additional weight, mounting hardware concerns, and long-term maintenance requirements, all of which can make the roof membrane more vulnerable to damage. Adding an HD ISO or gypsum coverboard can provide extra protection while increasing wind uplift resistance.

An HD ISO coverboard contributes additional R-value to the roof assembly while adding negligible weight. Gypsum coverboards, although heavier than HD ISO, provide more compressive strength, which could be a factor depending on the number, type, weight and attachment method of the solar components.

Just like when designing for hail, the attachment method can also impact the long-term performance of a roof membrane under a solar installation, as can the choice of the equipment mounts. Our photovoltaic brochure highlights how the use of a coverboard, attachment method and maintenance all work together to potentially extend the life of the roof assembly.

3. Vegetative or Ballasted Roofs

A vegetative roof, or a roof with other types of overburden, such as pavers, ballasted systems, or rooftop amenities, is subject to a unique combination of stresses. Additional weight, moisture, traffic, and other forces make the protection of the roof assembly paramount.

Designing an HD ISO or gypsum coverboard for these assemblies is best practices in these situations, as it greatly reduces the chances of membrane damage and subsequent compromise of the roof insulation.

4. High Traffic Roofs

Any roof with high-maintenance equipment and heavy foot traffic is a candidate for a coverboard. High-traffic roofs are common on schools, hospitals, data centers, and other buildings that require frequent rooftop access. Additionally, in the case of a building with a lot of rooftop mechanical equipment, there are numerous opportunities for membrane damage from dropped tools and wheeled carts transporting supplies for equipment repair and replacement.

In addition to coverboards, walkway pads are a good addition to further protect the membrane in high traffic areas**.

5. Lightweight Assemblies

The addition of a coverboard can enhance the overall durability and resilience of a commercial roof, especially one with an otherwise lightweight roof assembly. For example, an HD ISO coverboard can provide lightweight protection while contributing to the R-value of the assembly, thus allowing for the insulation under the coverboard to be slightly thinner and still meet R-value requirements.

A building owner committed to sustainability and long-term building resilience may also appreciate the additional advantages of this layer as part of the lightweight roof assembly: Insulation is the only building component that actually pays for itself in terms of reducing operational carbon (and, thus, the overall carbon footprint) of the building, the addition of an HD ISO coverboard can provide multiple benefits.

The Most Common Types of Coverboards

There are many different types of coverboards, manufactured for a variety of applications. The three most widely used are:

High-Density Polyiso (HD ISO)

HD ISO coverboards are lightweight, have a high R-value per inch, provide moderate compressive strength, and can be moisture and mold resistant. They offer increased thermal performance, protection from light to moderate foot traffic, and provide ease of handling and installation for installers.

GAF EnergyGuard™ HD ISO coverboards have an R-value of 2.5, which is significantly higher than their non-polyiso coverboard counterparts. They also meet the requirements of ASTM D3273 for resistance to mold growth***. Some HD ISO products may also achieve ANSI/UL 790 Class A Roofing Fire Resistance Rating over combustible decks.

Gypsum

Gypsum coverboards have the advantages of fire resistance, high compressive strength, and dimensional stability. The higher compressive strength may provide a higher degree of impact protection. They're easier to install than plywood and OSB but are heavier than HD Iso. They typically meet ASTM specifications for resistance to humidity, moisture, and mold growth.

Glass-Mat Gypsum

Glass-mat gypsum coverboards have a high-density gypsum core with fiberglass facers for enhanced compressive strength. They are fire-resistant as well as resistant to moisture and mold growth when tested to ASTM D3272*. GAF carries a variety of gypsum and gypsum-mat coverboards for any situation.

In addition to the above three, there are other types of coverboards on the market, including cementitious, perlite, wood fiber (like GAF STRUCTODECK®), and asphaltic (like GAF Sturdy-Dek®). These options are more commonly used on projects with more modest budgets or in applications that require torching or mopping applications of modified bitumen and built-up roof assemblies.

Value-Engineering Challenges

Coverboards are sometimes targeted in Value-Engineering efforts, with the claim being made that omitting them saves money and doesn't affect the warranty. However, failing to install coverboards can adversely affect the long-term performance of the roof assembly, potentially putting the owner's investment at risk.

When you calculate the costs of roof damage, repair, and replacement, as well as increased life cycle costs as a result of shorter replacement intervals, it makes sense to future-proof the roof with the added protection of a coverboard.

If you'd like expert assistance when deciding what type of coverboard is right for your next project, contact the GAF Building Science team at BuildingScience@GAF.com or schedule a virtual one-on-one meeting with a team member here.

*GAF warranties and guarantees do not provide coverage against hail except where additional hail coverage is purchased for eligible systems. Refer to applicable warranty or guarantee for complete coverage and restrictions, available at gaf.com.

**GAF warranties and guarantees do not provide coverage against traffic except where GAF walkways are applied. Refer to GAF.com for more information on warranty and guarantee coverage and restrictions.

***GAF warranties and guarantees do not provide coverage for mold or other biological growth.