When designing your next low-slope roof assembly, there are a number of single-ply roofing attachment methods to consider. Whether you choose a TPO, PVC, or EPDM membrane, the attachment method you select will typically be influenced by the building type and location, the rest of the roof assembly, and the construction schedule and cost. The most common single-ply roofing attachment methods are mechanical, induction-welded, adhered, and ballasted. Depending on the unique circumstances of your project, it may also make sense to employ a hybrid approach, or a combination of methods. Let's explore the main features, as well as the pros and cons, of each.

Mechanical Attachment

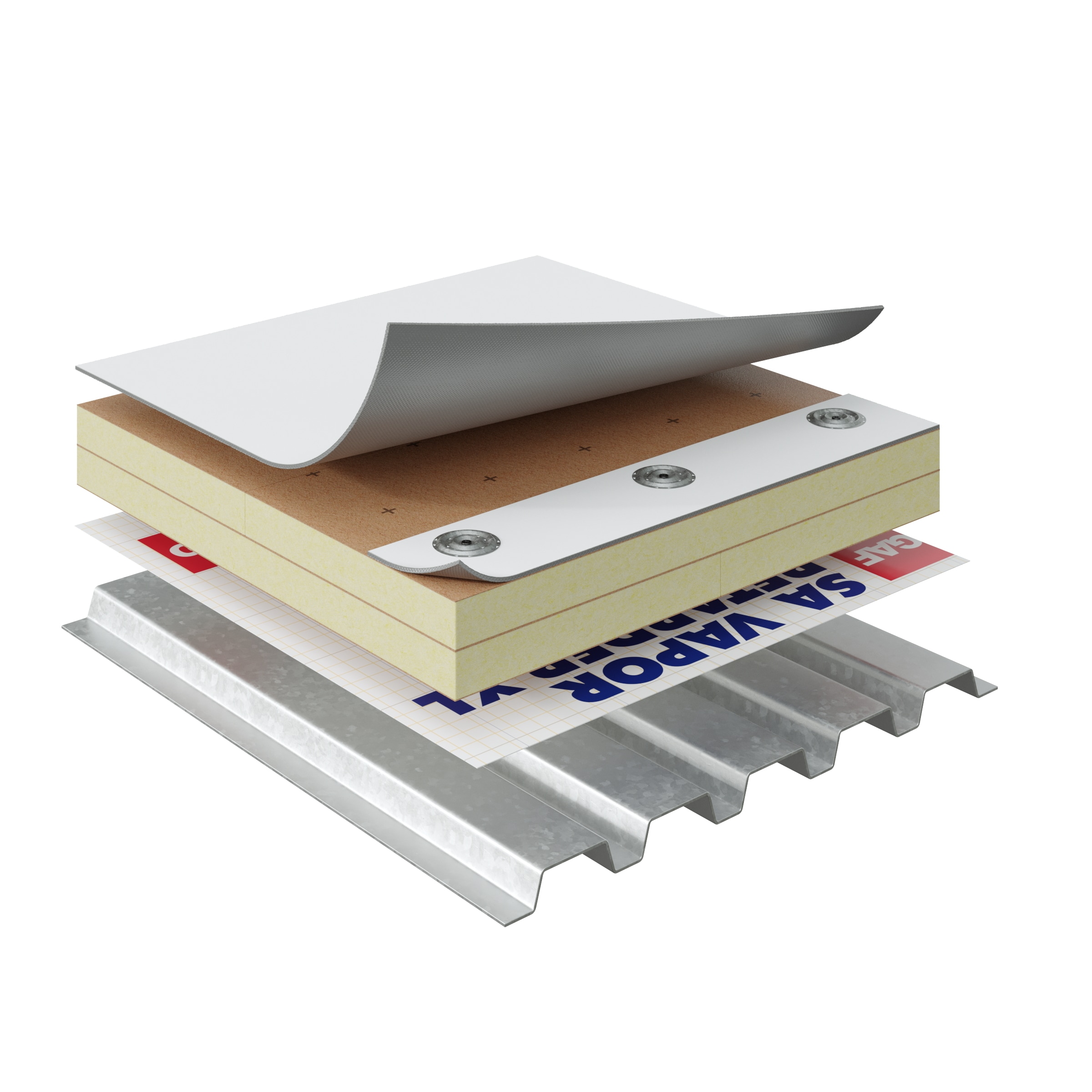

Mechanical attachment is achieved using mechanical fasteners (usually screws) set through metal plates designed to help spread the force imposed on the membrane and make the attachment more secure. The type and size of fastener is determined by the roof deck material and thickness of the total roof assembly. The fastener pattern and spacing is specified by the roofing manufacturer based on lab assembly testing and is often subject to local code requirements1.

Mechanical attachment is the most common single-ply roofing attachment method since it is fast, economical, and can be installed in various temperatures. However, in conditions of high wind uplift, or where the roof deck is not airtight, membranes installed mechanically may be subject to billowing. Billowing is caused by air that is pulled into the roof assembly, often by crosswinds providing an uplift force over the roof, causing the membrane to lift and flutter. In addition, exposed fasteners could be subject to damage from hail or heavy foot traffic if those conditions are present.

Finally thermal bridging (the transfer of heat between the interior and exterior of the building) through the fasteners could also be an issue depending on exterior climate and interior building conditions. You can find more information on the impacts of thermal bridging through fasteners here.

Induction-Welded

Induction welding is a type of mechanical attachment that uses numerous heat-welded attachment points that form strong bonds throughout the field of the roofing membrane. It uses a portable electromagnetic induction tool to weld specially coated mechanically attached plates on the surface of the insulation or coverboard to the underside of a PVC or TPO roof membrane, thus securing the membrane without the need for further penetrations.

Induction welding can be more economical than mechanical attachment because the same plates can be used to attach both the insulation and the membrane. It has the added advantages of having no exposed fasteners and strong wind uplift resistance due to more attachment points of the membrane compared to mechanically attached systems. This also reduces membrane billowing.

Adhered

An adhered membrane is one in which a roofing adhesive is applied to the underside of the membrane, and sometimes to the insulation or coverboard directly beneath the membrane as well. Adhered membranes have no exposed fasteners and provide exceptional wind uplift resistance by evenly distributing wind pressure across the membrane. Adhesives may also be a preferred attachment method on concrete decks where mechanical attachment can be difficult. Drawbacks can include the temperature range (above 40 degrees) required for their proper application, which might impact the construction schedule in colder climates. Additionally, odors and VOCs associated with some standard adhesives may be an issue when reroofing an occupied building. Depending on the type of membrane, quick-spray or quick-lay adhesives could be an option, as well as low-rise foam, which can be applied to only one surface rather than coating both the membrane and the substrate. In addition, newer low-temperature formula adhesives can be installed at temperatures as low as 20 degrees, and low-VOC adhesives can be used in situations where odor is a concern. Self-adhered membranes, which do not require a separate adhesive application, can shorten installation time if installed by a skilled contractor.

Ballasted

A ballasted roof consists of a single-ply membrane that is loose-laid over the roof substrate and held in place by large aggregate or pavers. This method offers strong protection against weathering and damage from hail and is most commonly used with thermoset membranes like EPDM membrane, rather than thermoplastics such as TPO or PVC membranes. While it can be a fast and cost-effective single-ply attachment method, it poses challenges: leak sources can be difficult to locate, and the roof structure must be designed to support the added weight of the ballast. In regions with high winds, building codes1 may restrict ballasted roofs due to the risk of wind uplift turning ballast into dangerous projectiles.

Hybrid Attachment

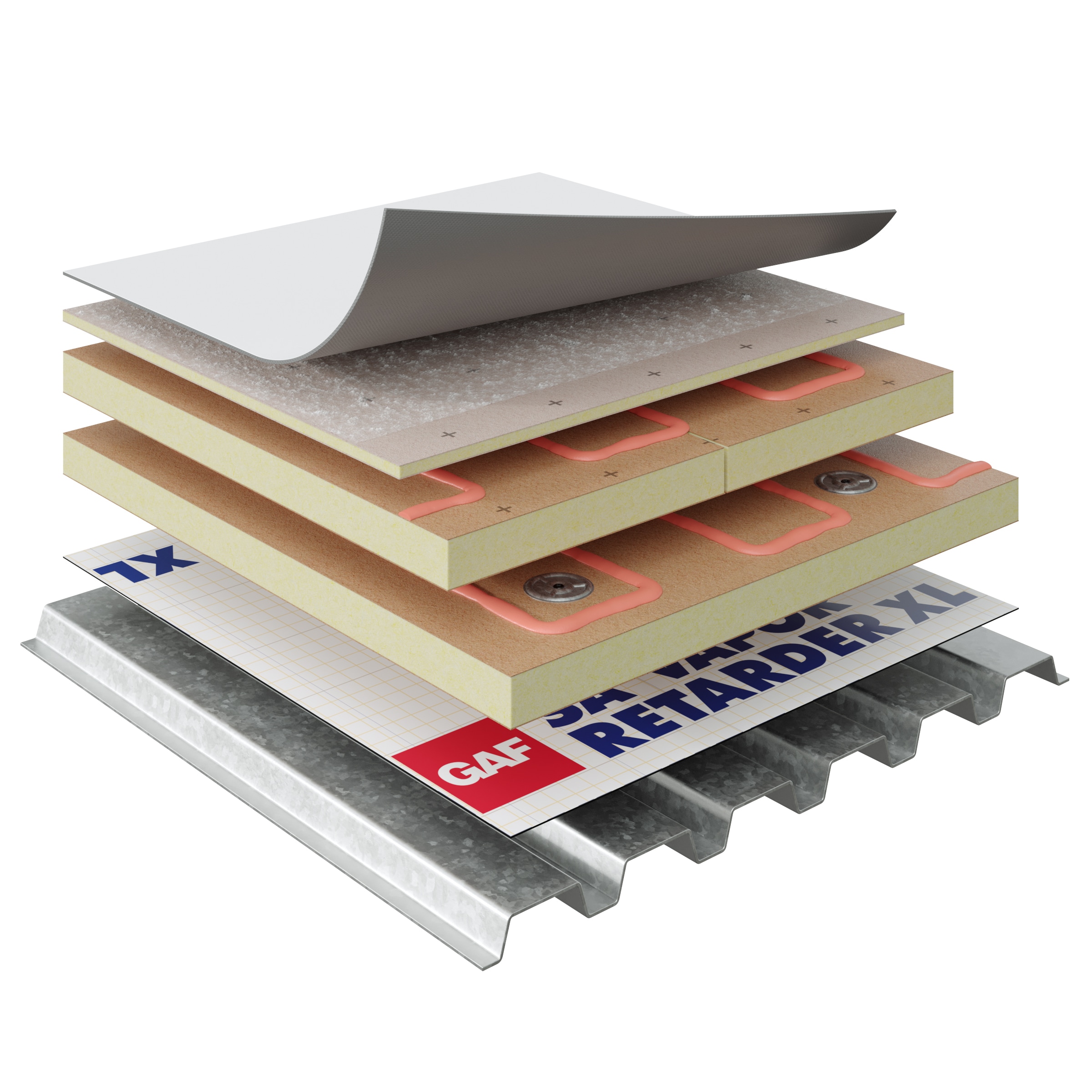

A hybrid attachment system combines the advantages of at least two single-ply roofing attachment methods, while potentially minimizing the possible disadvantages of each. One roof assembly to consider is where the insulation layers and cover board are mechanically fastened to the underlying deck. Depending on the climate zone, if the roof membrane is also mechanically attached, there could be concerns about thermal bridging or impacts from hail that could damage the fasteners. A possible solution is to adhere the single-ply roof membrane to the mechanically attached insulation or cover board below. However, with a fastener right under the membrane, it could telegraph through, creating a potential weak point at the fastener plate on a roof subjected to heavy foot traffic or rolling equipment.

In very severe hail assemblies, it is common to mechanically attach only the first layer of insulation and then adhere everything (second layer of insulation, coverboard and membrane) above it. This approach would minimize the impacts of thermal bridging while also protecting the fasteners from damage. In summary, many adhered assemblies fall into this category, as the first layer of insulation is often required to be mechanically attached for uplift resistance.

Choosing the Right Attachment Method

When selecting a single-ply roofing attachment method, you may want to start with the climate zone and typical weather conditions at your building site. In areas prone to high winds, induction-welded or adhered membrane systems can help prevent membrane billowing. For roofs exposed to severe hail or heavy foot traffic, an adhered or hybrid system may offer better protection by burying vulnerable fasteners within the assembly. In more moderate environments, a standard mechanically attached system may be the quickest and most cost-effective choice.

When both durability and thermal performance are key priorities, a hybrid system is often recommended, as it allows fasteners to be buried, yielding excellent performance. It is important for designers to be mindful that the familiarity and experience of local roofing contractors with various attachment methods can influence both the construction timeline and overall cost. This can be an overlooked, but is an important consideration in the decision-making process.

For more information or assistance in navigating single-ply roofing attachment methods for your project, reach out to the GAF | Siplast Building & Roofing Science Team at buildingscience@gaf.com.

1Always consult your local code requirements when designing and installing a roofing system.