When part of your building's roof has a flat section covered with a traditional low-slope roofing material (such as single-ply or modified bitumen membranes), while another part of the building's roof is steep-slope and covered with asphalt shingles, we refer to that as a "mixed roof."

A mixed roof can offer a nice aesthetic appearance; however, it can also bring unique challenges when it comes to keeping water out of the building. Here's what to consider.

Details Matter

The place where the two different roof technologies meet often requires special attention, says GAF Territory Manager Tim Rink. "Where the steep-slope roof ties into the low-slope roof is where potential problems can occur," he says. "Most building owners aren't even thinking about that or the problems that could arise at the transition points, especially if they use roofing materials from two different manufacturers."

If your mixed roof building uses material from two different manufacturers and you experience a leak at the transition point, it can be difficult to determine the cause of the leak. Additionally, it can become a finger-pointing game as each manufacturer blames the other, as Rink has observed. This can delay repairs and cause frustration for the owner.

Protection without the Hassle

When you choose materials from the same manufacturer, you eliminate these headaches. GAF manufactures both steep-slope and low-slope roofing materials that can be designed to work together at transition points.

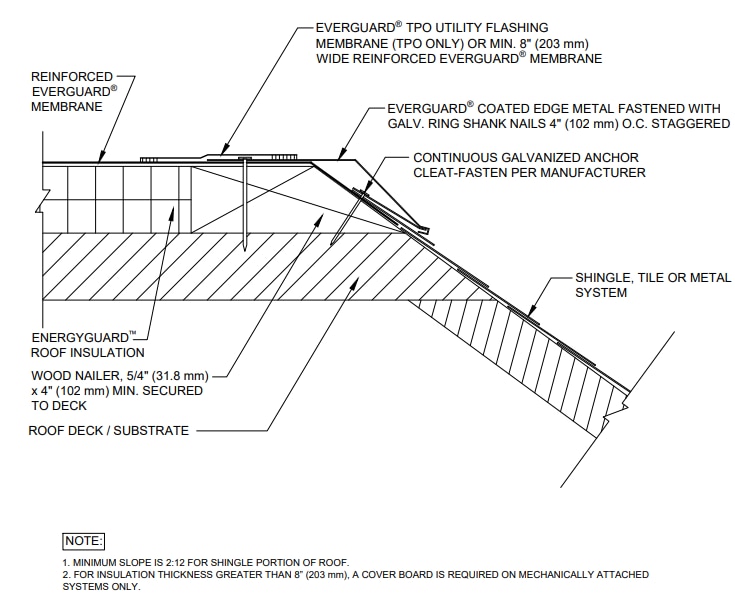

"We've got AutoCAD® details specific to these transition points, whether the low-slope solution involves single-ply membranes, modified bitumen membranes, or even coatings," explains Rink. "There is a specific way to install these materials to help prevent issues at the transition points." One such example can be seen in the detail below:

Many GAF Master Elite and Master Select contractors* are trained in the correct material installation methods for a mixed roof building. They also have to meet stringent requirements before earning their certification. For instance, they must be properly licensed in their state (if required), carry the right insurance coverage, receive training from GAF, and have a good reputation in their community.

In connection with guarantee issuance, a GAF field inspector will perform visual observance of the installation, including at transition points. Once the roof passes the inspection, the guarantee for both the flat and steep slope portions of the roof is issued in one document instead of multiple warranty and guarantee documents.

"Our Diamond Pledge with the Steep Slope Addendum roof guarantee is an NDL (no dollar limit) on both the flat roof and the shingle roof that ties it all together in one," explains Rink. "Should you experience an issue with the roof, you've got one phone call to make in order to get a fast and easy resolution to a potential leak issue- and no finger-pointing."

Extending Roof Life with Maintenance

Rink notes that there are options for building owners who perform annual service and maintenance on their mixed roofs to potentially extend the life of the roof. "There are maintenance incentives that can extend the guarantee on the roof if the owner performs annual maintenance. A 20-year roof might be able to be extended another five years if it is well cared for**."

When it's time to replace your building's mixed roof, remember this key takeaway: Using materials from a single manufacturer for both the low slope and steep slope sections of the roof can provide better protection and fewer hassles for building owners than using materials from multiple manufacturers.

Having a mixed roof doesn't have to mean you have to mix and match manufacturers. For additional information or guidance on your mixed roof, click here to be connected with someone who can assist you.

*Contractors enrolled in GAF certification programs are not employees or agents of GAF, and GAF does not control or otherwise supervise these independent businesses. Contractors may receive benefits, such as loyalty rewards points and discounts on marketing tools from GAF for participating in the program and offering GAF enhanced warranties, which require the use of a minimum amount of GAF products.

**See the WellRoof Guarantee Extension Addendum to the Diamond Pledge NDL Roof Guarantee for complete coverage and restrictions.