The roofing industry continues to discuss vapor retarders but should be discussing air barriers.

One of the primary purposes of a building envelope is to keep moisture out of a building. What makes this difficult is that water comes in many forms and can take many paths into a building. Therefore, building designers need to account for bulk water, capillary water, air-transported moisture, and water vapor, and deal with each of these with different forms of defense.

Water in its many forms

Bulk water (i.e., rain and snow) is kept out of buildings with roof membranes and facades of all types. Capillary water is primarily a ground-based issue involving water moving into and through the building envelope via capillary action. Foundation waterproofing and water barrier layers or components are used to prevent this intrusion. Air-transported water, as the name implies, is carried into a building by air that infiltrates the building envelope. Water vapor enters a building by the process of diffusion of water through the building envelope materials.

Figure 1: 1) Bulk water, 2) Capillary water, 3) Air-transported water, 4) Vapor diffusion

There is an order of priority for the prevention of water intrusion. Bulk water is most critical, capillary water is second, then air-transported water, and finally, of least concern—although still important—is vapor diffusion.

The design, manufacturing, and construction industries are quite good at keeping bulk water out of buildings. They are also quite good at keeping capillary water out of buildings. They have only recently begun to focus on the importance of keeping air out of buildings. That is why the International Energy Conservation Code (IECC), since 2012, requires all new buildings to include an air barrier. The main reason for air barriers is to keep conditioned air from escaping and exterior air from infiltrating, but air-leakage prevention in building envelope keeps the moisture in the air from passing into and out of buildings. It may be a secondary reason, but nonetheless, this reason is important!

You may be wondering why air-transported water is a bigger issue than vapor diffusion. Indeed, the roofing industry has discussed vapor retarders for decades, but only recently focused on air barriers. But "back in the day," multi-ply asphalt-based vapor retarders that were installed above the roof deck and below the insulation were also acting as very effective air barriers.

Diffusion versus air movement

Let's compare vapor diffusion and air-leakage from the perspective of how much water is transported for each process. Lstiburek1, et al, determined that—in a warm climate—approximately 1½ pints of water will diffuse through a 4'x8' gypsum board, and approximately 14 pints of moisture will be transported by air passing through a 1"x1" hole in that same gypsum board. The same research showed that—in a cold climate—approximately 2/3 of a pint of water will diffuse through a 4'x8' gypsum board, and approximately 60 pints of water will be transported by air passing through a 1"x1" hole in the same gypsum board.

Another way of stating this is: In a warm climate, air transports 10x more water than diffusion, and in a cold climate, air transports 100x more water than diffusion. This is why air-transported moisture is much more critical to prevent than water vapor that enters a building by diffusion.

It has been suggested that air infiltration and exfiltration make up 25 to 40 percent of the total heat loss in a building in a cold climate and 10 to 15 percent of total heat gain in a hot climate.2 This is likely why the IECC have air-barrier requirements and do not have any significant vapor retarder requirements for building envelopes.

2nd law of thermodynamics

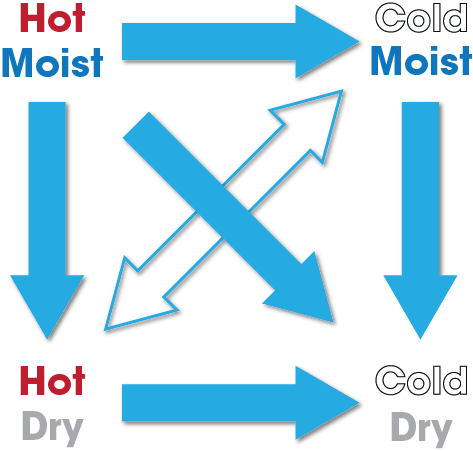

There is one simple rule that defines how heat, air, and moisture move—the 2nd law of thermodynamics. That sounds like a mouthful, so let's distill it. What it means in terms of building and roofing science is this:

- Hot moves to cold

- Moist moves to dry

- High pressure moves to low pressure

Heat, moisture, and pressure always equalize when possible (i.e. if paths are available to do so). That's why there is a drive for warm, moist air to leave a building during winter when it's cold and dry outside.

For roof systems, the 2nd law of thermodynamics helps explain why—during the cold winter months—warm, moist interior air (e.g., 75F, 50% RH) infiltrates up into a roof system that doesn't have a vapor retarder/air barrier in the system. The warm, moist air equalizes to the exterior where the air is cooler and drier. There can be other reasons why this happens, like the stack effect, wind and associated membrane billowing, and internal pressurization from mechanical systems. So let's discuss those, too.

Air Movement

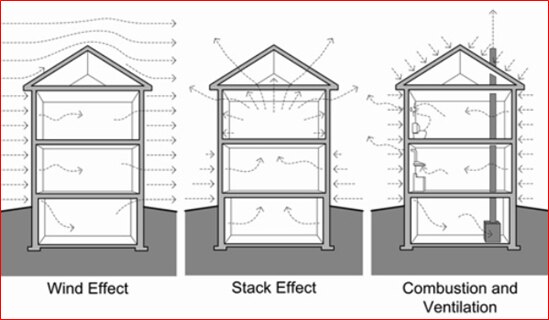

The stack effect, in laymen's terms, is the fact that warm air rises. In a tall narrow column, such as a skyscraper, this effect can be very pronounced. When warm air rises, it creates a higher pressure in the upper interior portion of a building. That increase in pressure also means the warm, moist air will escape through any pathways that are available. It will escape 'into' the roof or any air passage that goes to the exterior. (That's why air barriers are now an energy code requirement for new construction. More on that in a bit.)

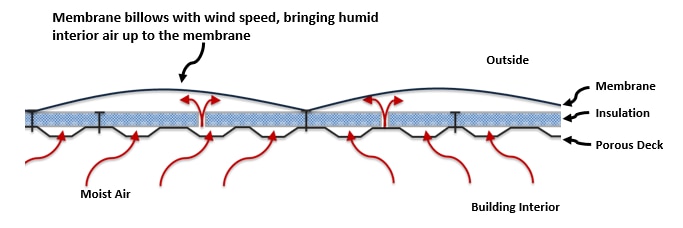

Membrane billowing occurs when wind creates a negative pressure above a roof system and lifts the membrane between the rows of fasteners in the seams. A billowing membrane brings interior air into the roof system regardless of temperature or moisture levels.

Air conditioning and heating equipment force air through ductwork and into the interior of a building. By forcing conditioned air into a space, the space can become somewhat pressurized. Not to a great extent, but enough to create an imbalance between the interior and the exterior, forcing interior air into the roof system.

Figure 3: Processes that create air-flow across the building envelope. SOURCE: Building Science Digests, BSD-014: Air Flow Control in Buildings, John Straube, October 15, 2007

A less desirable scenario for air and moisture infiltration into a properly installed roof assembly is to use a mechanically attached (MA) system with a single layer of insulation without a vapor retarder/air barrier (VR/AB). The MA system billows; the lack of VR/AB allows warm moist air to enter the roof system; and the board joints allow a direct path for air flow from the deck to the membrane.

Figure 4: A less desirable roof-design scenario for air and moisture infiltration into a roof assembly.

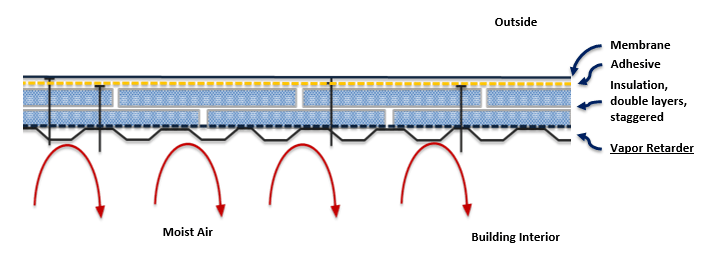

A more desirable scenario is an adhered roof system with multiple layers of insulation (with board joints offset and staggered) over a VR/AB. This system helps lower the risk of these detrimental processes from occurring. The end result can be a roof system with better longevity and thermal performance, and a building with improved energy efficiency. (Of course, actual energy savings may vary based on a number of factors, like climate zone, utility rates, etc.)

Figure 5: A roof design that improves longevity and thermal performance.

Vapor Retarders and Air Barriers

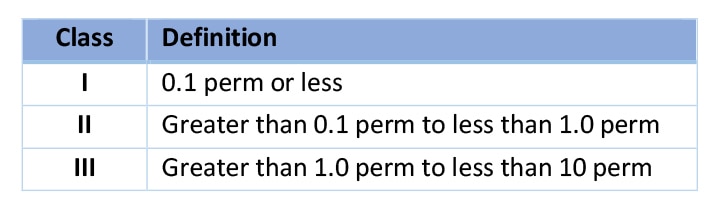

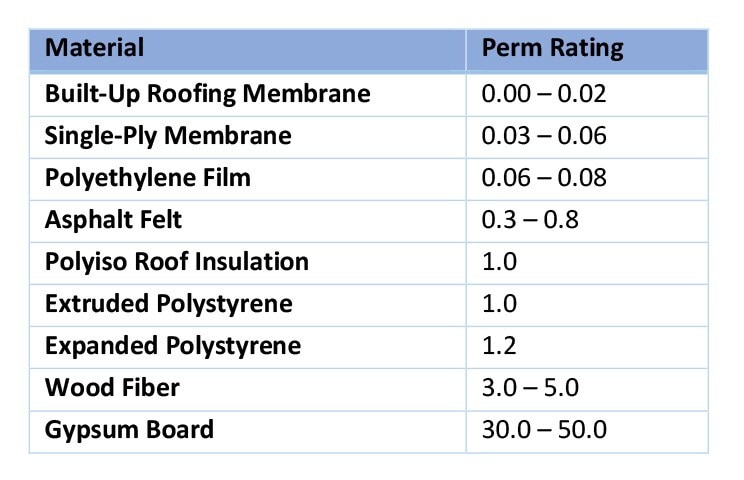

Vapor retarders do just as they are named—they reduce vapor diffusion, but not all vapor retarders are equal. There are 3 classes of vapor retarder materials, as shown in the figure. The lower the perm rating, the less diffusion occurs through a material. Most roof membranes are Class I vapor retarders. A single layer self-adhered, bituminous vapor retarder has a perm rating of 0.03 perms. Plywood (1/4" thick, Douglas fir, exterior glue) is a Class II vapor retarder with a perm rating of 0.7 perms. The same plywood with interior glue is a Class III vapor retarder with a perm rating of 1.9 perms. Perm ratings for additional roofing materials are shown in the figure. Remember, these are material ratings; the full system needs to be designed and installed correctly for proper functionality.

Figure 6: Three classes of vapor retarders

Figure 7: Perm ratings of common roofing materials.

From a designer's perspective, if a vapor retarder is needed, which class should be used? If a Class I vapor retarder is used, the concern is that any moisture (e.g., construction moisture due to installation methods, weather, etc.) that enters a roof system won't be able to dry out. It's often a good idea to select a vapor retarder that will allow some amount of drying from diffusion. Exceptions to this idea include roofs over indoor swimming pools and other high-humidity producing activities or processes. Another exception is a Class I vapor retarder should be installed over a new concrete deck to prevent the moisture in the concrete from drying into the roof system.

Here's a key takeaway—all vapor retarders block air, but not all air barriers block vapor diffusion. That means that when we use a vapor retarder in a roof system, it's also acting as an air barrier. The caveat is that the vapor retarder needs to be sealed at all perimeters and penetrations, and tied to the wall air barrier so air does not bypass the vapor retarder layer. So, practically speaking, all vapor retarders are air barriers if they are installed to block the passage of air.

Moving Forward

The traditional way of designing roofs with vapor retarders is to install an asphaltic vapor retarder (a single layer modified sheet or a double mopping of asphalt) either directly to the deck or over a fastened hardboard. What if that hardboard or plywood deck was recognized to be the air barrier layer, but had a moderate or high perm rating? Since air movement brings 10-100 times more moisture as compared to diffusion, perhaps we should be considering the use of a Class II or III vapor retarder (e.g., hardboard or plywood deck) installed to be an effective air barrier that also allows some drying potential? The wall industry has been doing this for quite some time. Should our roof systems be designed similarly? A gypsum-fiber board has a perm rating of approximately 24 to 30 perms, depending on thickness. If this board is fastened to a steel deck and the joints and transitions are taped, it could be an effective air barrier that allows some drying. Something for roof designers to consider!

Roof system design is always the responsibility of the designer, but perhaps the designers in the roofing industry can find some takeaways from the wall industry. There is always more to learn and understand about the building science of our roof systems.

1Building Science Corporation, Build Boston—2005, Thermal and Air Leakage Control, ppt from Betsy Pettit, AIA

2"The Hidden Science of High-Performance Building Assemblies," Environmental Building News, November 2012